Anti-Corrosion Wraps for Industrial Infrastructure

Durable Anti-Corrosion Wrap Applications for Industrial Infrastructure

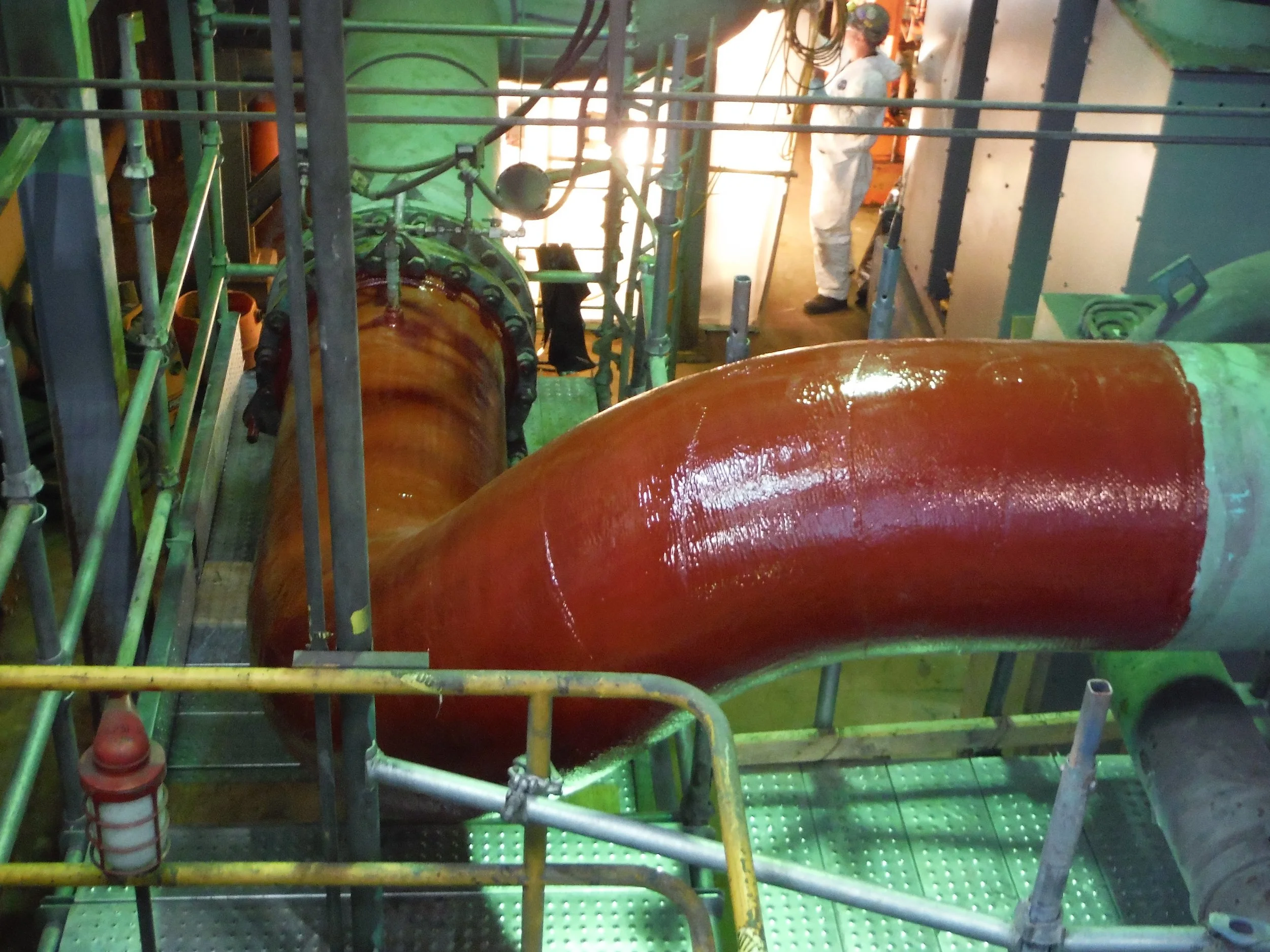

Every industrial repair requires a tailored approach that accounts for material condition, environmental exposure, and application constraints. Traditional repair methods often rely on abrasive blasting, an option not always feasible or safe for sensitive or complex components. A&G Industrial offers anti-corrosion wrap applications that eliminate the need for abrasive blasting, making them ideal for fast, effective protection in challenging conditions.

Our wrap systems are engineered for long-lasting performance across a range of surfaces, including:

Pipes

Irregular fittings

Bridge spans

Couplings

Valves

Weld cutbacks

Exothermic welds

Whether exposed to water, chemicals, or temperature extremes, our anti-corrosion wraps provide a strong barrier that prevents oxidation and surface degradation. They conform easily to difficult geometries and can be applied to both wet and dry surfaces—offering flexibility where traditional coatings fall short.

Paired with our Managed Area Programs (MAPs) and Corrosion Surveys, we identify and prioritize high-risk areas to ensure complete protection. Our industrial painting and coating services further enhance surface resilience—creating a comprehensive, turnkey corrosion control strategy.

Key Benefits of A&G Anti-Corrosion Wraps

No Abrasive Blasting Required

Eliminates the need for abrasive surface prep, making it safer and more suitable for sensitive environments or hard-to-reach areas.

Fast, Non-Intrusive Installation

Wraps are easy to install with minimal disruption to operations, helping reduce downtime and labor costs.

Regulatory Compliance

Meets a range of industry standards for corrosion protection and workplace safety, supporting compliance in regulated environments.

Cost-Effective Maintenance

Reduces the frequency of repairs and replacements, supporting longer maintenance cycles and delivering measurable cost savings over time.

Long-Term Durability

Designed to withstand extreme conditions including moisture, chemicals, and temperature fluctuations, extending the life of your equipment.

Industry Versatility

Ideal for use in utilities, wastewater treatment, oil & gas, and power generation facilities, especially where space, time, or access are limited.

Backed by CFES Engineering Expertise

All A&G anti-corrosion wrap applications are supported by our partner, Carbon Fiber Engineering Solutions (CFES). From corrosion assessments to material validation and site-specific repair recommendations, CFES provides the technical foundation behind every solution we install. Their involvement ensures that each application is based on solid engineering, rigorous testing, and proven performance—giving you peace of mind that your infrastructure is protected by more than just a wrap.

Explore CFES’s services in:

Condition assessments and corrosion surveys

Repair design and technical validation

Advanced non-destructive evaluations

Material testing and performance modeling

INDUSTRIES WE SERVE